Turbochargers Explained

Ever wondered how WRC cars manage to deliver 300 bhp and above from an engine that, by rule, cannot exceed 2.0 liters of displacement? How on earth do the heavy, low-revving diesel engines in cars today stay competitive? Or what is it that makes it possible for the Bugatti Veyron to break the 1000 bhp threshold? Well, it certainly isn't witchcraft. By means of "forced induction", turbochargers today boost the automotive industry to a new direction of smaller, more-efficient and bloody good fun engines.

Volkswagen like to brand their most successful turbo diesel range as TDI while Porsche, being more plain about it, call their turbocharged cars, Porsche (insert model here) Turbo. BMW, on the other hand, would never hesitate to utter their own terms like "bitrubo" or "TwinPower" whenever describing the latest M5 engine. The variety of depicting turbocharged cars is bountiful, but essentially the principles of work remain the same in every case.

Beware reader, as I am now going to get technical:

In order to understand how a centrifugal turbocharger works, one must also have some basic knowledge on how four-stroke, piston engines work. We have an engine block that contains the cylinders, right? Inside each cylinder, a piston moves up and down. Every movement made is a phase, a stroke. First we have intake – a mixture of fuel and air is sucked into the cylinder. Compression is the second stroke where the cylinder moves up and...well...compresses the molecules in the mixture. The next ignition stroke is downwards as the piston experiences pressure coming from the combustion of the mixture. The exhaust stroke has the job to expel the remaining gases through the exhaust valve. Then the intake valve lets in a new batch of fuel mixture and thus the process is repeated.

However, as far as turbochargers are concerned, exhaust gases are not exactly throw-away material. Put simply, the turbocharger utilizes the energy of exhaust to compress the the newly arrived batch of air which is to be shoved in the cylinder. More air molecules means that more fuel can be injected into the mixture and more fuel means more power.

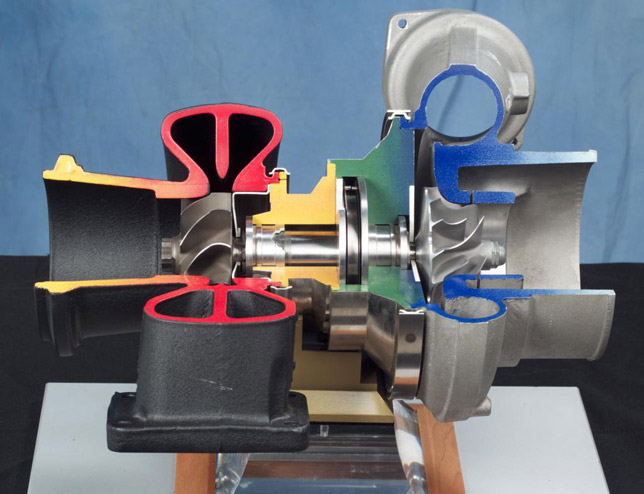

Before those exhaust gasses reach the exhaust system they go trough a turbine connected to a shaft. The more exhaust that goes through the turbine blades, the faster they spin. On the other end of the shaft we find a compressor which welcomes fresh air from the atmosphere, compresses it using the force of the turbine and then feeds it into the engine. To further increase the efficiency of the turbocharging system, an intercooler is added – it looks much like a car radiator but instead of containing cooling fluid, it holds the compressed air from the compressor. Air is denser when cooler and that's exactly what the intercooler does – it cools the incoming air.

There are issues however. First of all, a turbine amidst the flow of exhaust is essentially an obstacle. The exhaust stroke has to deal with more back-pressure thus being slightly less efficient. A functional turboshaft has to handle extreme forces (speeds go up to 150 000 rpm within the turbocharger) so a special kind of baring is needed – liquid ones or state-of-the-art ball bearings. The latter is more efficient but more expensive. Then there's the dreaded turbo lag. The problem here is that when you put your foot down, the response is far from electric. The turbine needs some time to kick off and start spinning the compressor blades. That's why at low engine rpm one can't really tell if the car has a turbo or not.

There are various ways to tackle this nuisance. Make things smaller and lighter. Tiny turbochargers will grant you that off-the-line jolt but won't be too good on the upper rpm range. Besides, if too much exhaust starts going through a relatively small turbine things may get hot and disbalanced. Usually however, there's the wastegate in most turbines – a valve that knows how much exhaust passes through and regulates the flow by simply diverting some of the gases away from the turbine. Some companies have started putting more than one turbochargers in their cars. One small and the other, big. The small one guarantees a more immediate response while the big one takes over at higher speeds.

Essentially, that's the story with turbochargers. We can further dive into numbers and calculations about pressure and efficiency but this, I think, is already nerdy enough. Hopefully some of you learned something new while others refreshed their memory on how the turbocharger brings easy power to our everyday lives.