CVTs – The Perfect Transmission?

A continuously variable transmission (CVT) is a type of automatic transmission but operates very differently than older fluid-based automatics. CVTs are mechanically-based transmissions and provide more useable power, better fuel economy and smoother driving than traditional automatics. It should be noted that CVTs have been around for years in other motorized applications. Vehicles such as snowmobiles and some off-road recreational vehicles have utilized CVTs for decades. Only just recently has the technology seen mainstream automotive use.

A continuously variable transmission (CVT) is a type of automatic transmission but operates very differently than older fluid-based automatics. CVTs are mechanically-based transmissions and provide more useable power, better fuel economy and smoother driving than traditional automatics. It should be noted that CVTs have been around for years in other motorized applications. Vehicles such as snowmobiles and some off-road recreational vehicles have utilized CVTs for decades. Only just recently has the technology seen mainstream automotive use.

How they work

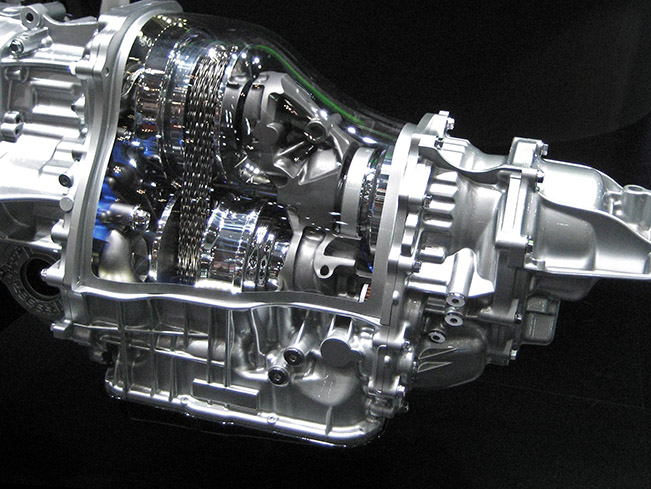

Conventional automatic transmissions have sets of gears inside their housings that provide different gear ratios or speeds. Control units sense a vehicle's speed and other parameters and use that information to shift the transmission's gears. The user just puts the transmission in the appropriate mode with the gear selector switch (P-R-N-D-L). A CVT uses a similar selector switch but replaces the complex gears sets common in automatic transmissions with two simple variable-diameter pulleys, each shaped like a pair of opposing cones, with a metal belt running between them. The way it works is that during operation the pulleys move in and out such that a drive belt between moves higher on one pulley, lower on the other and this provides a numerical gear reduction. You can picture this roughly as the way a 10-speed bike works, by routing the chain over smaller or larger gears to change the gear ratios. The gearing effect with a CVT is essentially "continuous", hence the nomenclature.

What they are like to drive

The controls for a CVT-based car are the same as an automatic-based car: Two pedals (gas and brake) and a P-R-N-D-L-style shift pattern. When driving a car with a CVT, you won't hear or feel the transmission shift, though. It simply raises and lowers the engine speed as needed, calling up higher engine speeds (or RPMs) for better acceleration and lower RPMs for better fuel economy while cruising. Some people find that driving a CVT-based automobile is a little disconcerting because they sound different when being driven.

Advantages of CVTs

Internal combustion engines do not develop constant power at all speeds; they have specific speeds where either torque, horsepower, or fuel efficiency are at their optimum levels. Because a CVT can theoretically adjust to any gear ratio, engineers can program them to give maximum performance in all these situations.

Disadvantages of CVTs

The CVT's biggest problem has been user acceptance. Because the CVT allows the engine to rotate at any speed, the noises coming from under the hood can sound odd to ears accustomed to conventional automatic transmissions. Automakers have gone to great lengths to make the CVT feel more like a conventional transmission. For example, many CVTs are now programmed to simulate the "kick-down" feel of a regular automatic when the pedal is floored.

Reliability of CVTs

Because early automotive CVTs were limited as to how much horsepower they could handle, there has been some concern about the long-term reliability of the CVT. This has not proven to be a problem, though. Advanced technology has made the CVT quite robust and reliable. Nissan has more than a million CVTs in service around the world and says their long-term reliability is comparable to conventional transmissions.

The future of the CVT remains to be seen. In spite of the obvious efficiencies of CVTs, customers can be fickle and may prefer and older technology. Give it a few more years and we should know how user acceptance plays a role in the adoption in CVT technology.

Source: Team Nissan North