ARPRO can save 16 million tonnes CO2

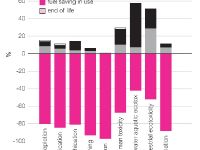

ARPRO® has achieved excellent environmental results in an independent life cycle assessment. The assessment calculates a comparative CO2 (global warming potential) figure for the production of an ARPRO seat core, and results show that ARPRO delivers an environmental benefit twelve times that of its impact.

"As the focus on environmental performance intensifies, companies are increasingly expected to demonstrate proven results for their products," explains Paul Compton, JSP's Executive Vice President and Chief Operating Officer - Europe. "Life cycle assessment is the most widely recognised technique to assess the environmental impacts of a product from raw material supply through the point of use and to end of life (recycling or disposal)."

The aim of the independent study was to produce an ISO-compliant life cycle assessment of a seat core manufactured from ARPRO, a lightweight and versatile material that helps to reduce weight, energy consumption and cost. After studying the global warming impact, the CO2 reduction resulting from an example ARPRO seat core was 265kg CO2 (e) over the vehicle lifetime.

"If this saving is applied to the number of cars sold annually, an environmental saving of nearly 16 million tonnes of CO2 (e) could be achieved," states Compton. "Assuming a vehicle lifetime of 100,000km, just changing the seat can enable a reduction in CO2 (e) of 2.65 g/km, over 13 per cent of the 2012 EU target reduction from 140 to 120 g/km CO2 (e)," says Compton.

The environmental impact of the seat core production was calculated through the stages of raw-material production, ARPRO production, moulding and component assembly. Creating an ISO-compliant study required an approved protocol to be followed and peer-review by a second, independent life cycle assessment expert. "This was important to JSP as it enables our customers to have confidence in the data and findings delivered".

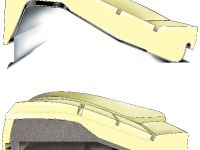

Key to the CO2 (e) savings is the ability to deliver weight reductions of up to 35 percent, achieved by replacing the heavy steel anti-submarining safety ramp with ARPRO. ARPRO is strong and resilient enough to enable the ramp to be incorporated into the seating itself, replacing the traditional metal structure and contributing to a more versatile vehicle platform.

"JSP developed ARPRO seating solutions for three of 2008's major European car launches, including the Volvo XC60, and more innovative solutions are in the pipeline. ARPRO delivers seating structures that preserve safety, enable flat floors and cost-effective H-Point variation for multiple platforms, save weight and provide a positive environmental impact."

ARPRO is 100 percent recyclable making it increasingly ideal for automotive components as car makers strive to meet the 2005 ELV Regulations which stipulate a reuse and recycling target of 85 percent of the weight of the vehicle.

"Scientific proof of the positive environmental impact of ARPRO adds further support to vehicle makers looking to dramatically reduce carbon emissions. Further potential environmental savings have been identified as part of the investigation and are already being acted upon," concludes Compton.